In the constantly shifting space of e-commerce, 2025 is a critical year for brands that want to grow quickly while being sustainable. Consumer expectations for everyday purchases prior to 2025 are at record levels; customers want faster deliveries, seamless returns, and personalized experiences. Additionally, brands must rethink their overall logistics strategy. One of the most transformational changes in this changing landscape will be the adoption of multi-warehouse management.

Now, multi-warehouse management is a necessity. Let’s explore why this strategy is critical for e-commerce brands looking to scale in 2025 and beyond.

The E-commerce Boom: Opportunity Meets Complexity

The growth of e-commerce has skyrocketed in the last few years, propelled by a range of global events, innovations in technology, and changes in buyer behavior. Recent reports indicate that the global e-commerce industry is likely to exceed $7 trillion by 2025, with online shopping becoming the default shopping method for millions of consumers around the world. However, with growth comes complexity.

Multi-Warehouse Management: Definition

Multi-warehouse management is a strategic use of multiple storage facilities across different locations. Instead of relying on a single hub, businesses distribute inventory across several warehouses, often closer to key customer bases or logistics hubs.

This approach is powered by advanced Multi Warehouse Management Systems and Order Operations Platforms, which synchronize inventory, automate order routing, and provide real-time visibility across all locations.

Why Multi-Warehouse Management Is Essential in 2025

1. Faster Delivery Times = Happier Customers

Speed is a king in e-commerce. By strategically placing inventory in multiple warehouses, brands can fulfill orders from the location nearest to the customer. This reduces transit time, enables same-day or next-day delivery, and enhances customer satisfaction ultimately driving repeat purchases and brand loyalty.

2. Reduced Shipping Costs

Shipping costs are a major pain point for e-commerce businesses. The farther a package travels, the higher the cost. Multi-warehouse management allows brands to leverage regional fulfillment, using ground shipping instead of expensive air freight.

3. Improved Inventory Accuracy and Availability

Inventory mismanagement can lead to stockouts, overstocking, and lost sales. With multi-warehouse management, brands can synchronize inventory in real time across all locations, ensuring accurate stock levels and smarter allocation.

Advanced WMS platforms use predictive analytics to forecast demand, helping businesses stock the right products in the right places. This is especially crucial during peak seasons or promotional events when demand surges.

4. Enhanced Business Resilience

In an unpredictable world, resilience is key. Natural disasters, supply chain disruptions, or regional lockdowns can cripple operations if a brand relies on a single warehouse. This flexibility ensures that customer experience remains uninterrupted, safeguarding brand reputation and revenue.

5. Scalability Without Chaos

Scaling an e-commerce business is about fulfilling more, faster, and better. Brands can expand into new markets without overhauling their entire logistics infrastructure.

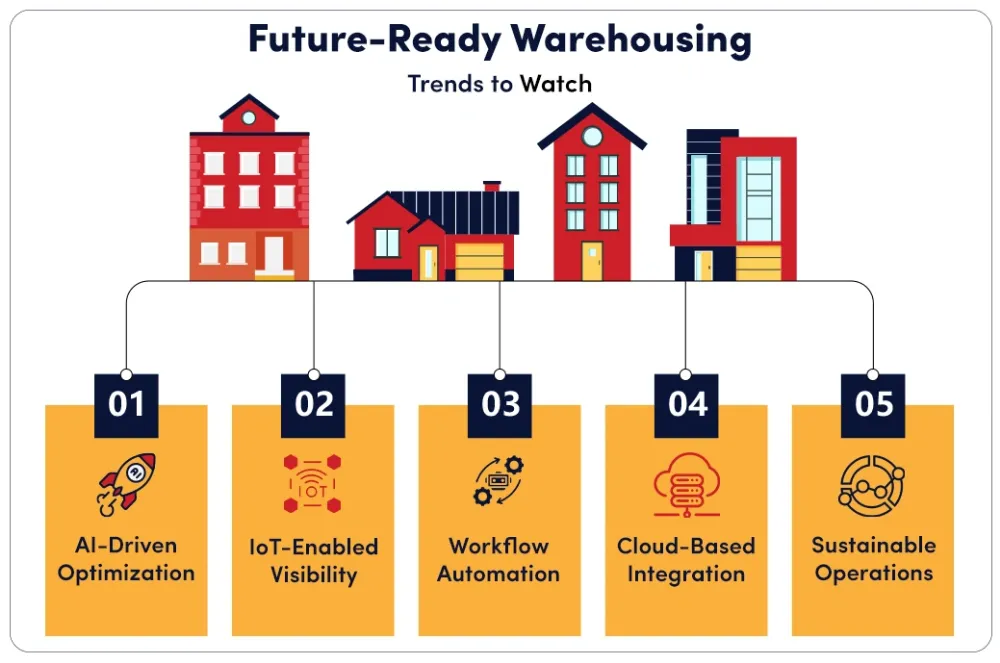

Future Trends Shaping Multi-Warehouse Strategies

The future of Multi-Warehouse Management is driven by AI, IoT, and predictive analytics. Smart automation, robotics, and real-time data insights will optimize inventory flow and logistics. Cloud-based integrations and sustainable warehousing practices will further enhance agility, efficiency, and responsiveness to market demands.

The Role of Technology in Multi-Warehouse Management

Technology is the backbone of successful multi-warehouse strategies. In 2025, we’re seeing a surge in these tools that offers:

- Real-time inventory visibility

- Automated order routing

- Barcode and RFID scanning

- Predictive demand forecasting

- Integration with sales channels

Overcoming Challenges in Multi-Warehouse Management

Managing multiple warehouses comes with challenges like inventory visibility, order accuracy, and real-time coordination. Businesses overcome these by using centralized warehouse management systems, automated inventory tracking, and data-driven forecasting by ensuring faster fulfillment, reduced costs, and improved operational efficiency across all locations.

LionO360 ERP: Smart Warehouses, Smarter Strategies

Managing multiple warehouses is essential to realizing this opportunity. LionOBytes LionO360 ERP is among the top ERP solution providers. It transforms warehouse management through the combination of smart automation with strategic business insights. With real-time visibility in data tracking, predictive analytics, and interoperability between departments, LionO360 guarantees that all decisions related to the warehouse are data-driven, and adaptable. The user-friendly dashboard displays complete visibility of stock levels, order statuses, and vendor performance to enable proactive planning and faster agility. Book your free ERP demo here.

Also Read: What is Inventory Management?

Frequently Asked Questions

What is multi-warehouse management?

Multi-warehouse management is a strategic approach where businesses use multiple storage facilities across different locations.

Why is multi-warehouse management becoming a need for e-commerce brands today?

Consumers demand faster deliveries, seamless returns, and personalized experiences. This strategy helps brands meet these demands, reduce costs, improve inventory accuracy, enhance resilience, and scale sustainably.

What are the key benefits of implementing a multi-warehouse strategy?

- Fulfilling orders from the nearest location reduces transit time, leading to happier customers and repeat purchases.

- Leveraging regional fulfillment allows for more cost-effective ground shipping instead of expensive charges.

- Real-time predictive analytics ensure accurate stock levels and more intelligent allocation, preventing stockouts and overstocking.

What challenges are associated with multi-warehouse management, and how can they be overcome?

Challenges include maintaining inventory visibility, ensuring order accuracy, and coordinating operations across multiple locations. This ensures faster fulfillment, reduced costs, and improved operational efficiency across all warehouses.