If you are processing a large volume of customer deliveries every day, ensuring accurate and faster delivery may become a cumbersome process that you cannot achieve without having the Pick, Pack, and Ship module in ERP system.

And when it comes to customer satisfaction, it has become crucial for your high-performing business to provide faster and error-free delivery to your customers. Here inclusion of ‘Serial Numbers’ and ‘Lot Numbers’ also plays a significant role.

Certainly, it is directly related to order fulfillment that involves several steps to ensure success. Yes, we are talking about the product journey from warehouse to doorstep delivery to customer.

And, this journey requires maintaining product quality, accuracy in the order delivery, and timely delivery to the customer. Here, Pick, Pack, and Ship workflow comes into the picture.

So, let’s understand how navigating the pick, pack, and ship workflow can impact the product journey from ‘Warehouse to Customer’.

Pick Process

So, you might have multiple warehouses; however, in each warehouse, you will have one thing in common i.e. having aisles, racks, and bins wherein your inventory items are managed. And the picking process starts from here.

Now, when your customer places an order, your warehousing team needs to locate the order first, verify the order quantity, and perform quality checks. Once these things are done, you allow them for packing preparation.

When this process is performed manually, you may lose in terms of stock unavailability or other inaccuracies. But when you have a proper system equipped with the pick pack and ship capabilities, you can effectively manage this process. In turn, you can have seamless and efficient order fulfillment.

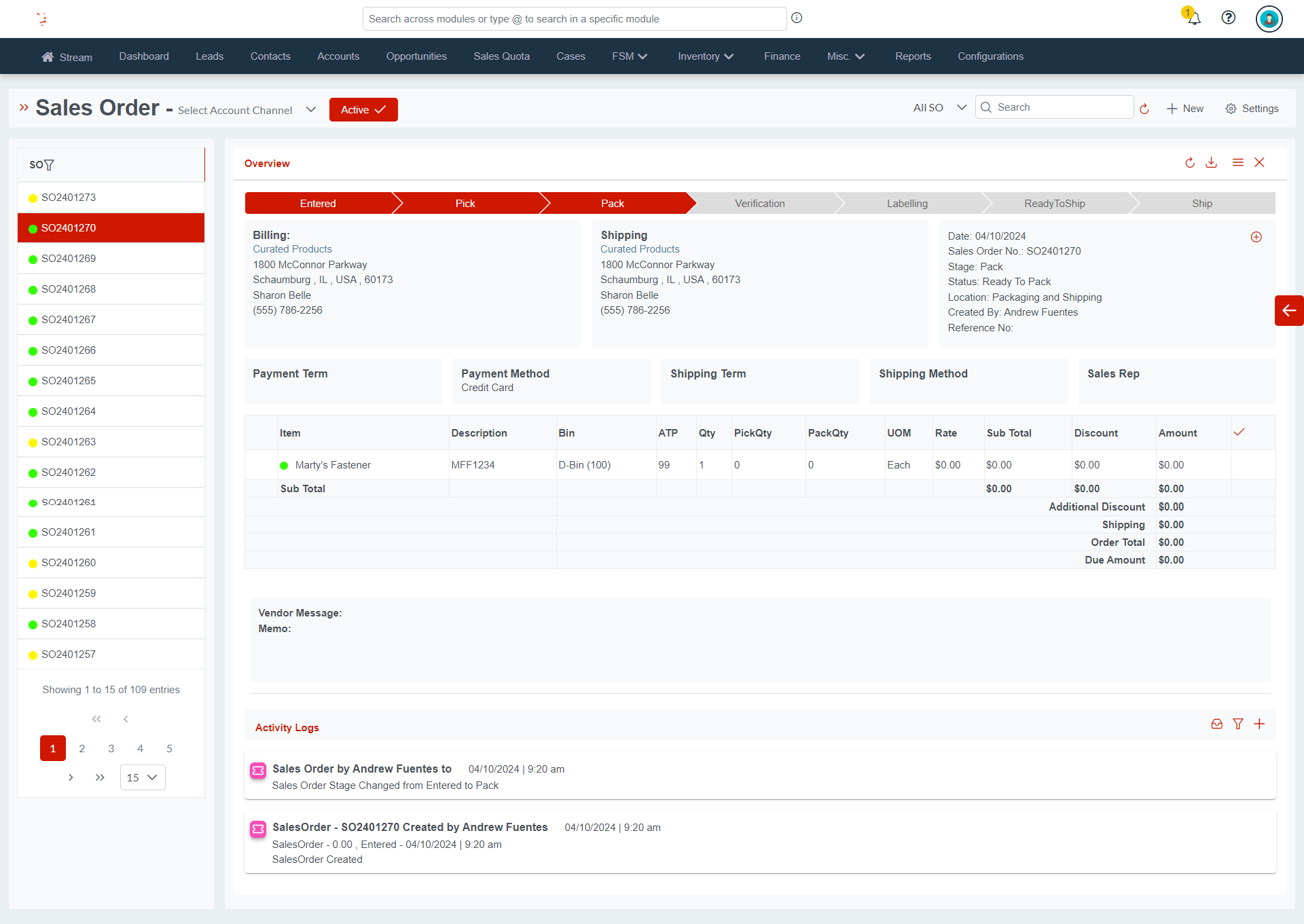

With LionOBytes, you can efficiently manage your sales orders and ensure accurate and faster delivery as our LionO360 ERP system comes with the necessary functionality i.e., ‘Pick, Pack, and Ship’.

All you can do is just create a pick list first based on orders you received from your customers. Our system allows you to quickly locate the products, enables you to effectively verify the available inventory count, and performs quality control.

In turn, this will help you speed up the order-picking process in your warehouse with accuracy for a smoother packing process.

Pack Process

So, your order-picking process is done right. Now, the next step is to pack the order that also imbibes order verification and package labeling so that it can better align with the shipping process.

Certainly, LionO360 helps you to effectively process the order packing process as well as ensure seamless product verification and simplified labeling process. With this, your order is ready to ship.

With LionO360, you enjoy the streamlined packing process with reduced operational costs and minimized errors. When everything goes accurately and effectively, your customers get satisfactory delivery to their doorstep.

Ship Process

Once your orders are ready to ship, the final step is to process shipping for the same. You can choose your preferred shipping method and shipping term. Here, having the right tool or system can better manage the shipping price for your customer orders.

In the LionO360 system, your warehousing team can easily generate shipping labels, effectively manage logistics, streamline the order fulfillment process, and accelerate customer delivery.

Moreover, you can even automate pick and pack processes using our system, which saves time and maximizes efficiency.

Our system is also facilitated with ‘Serial Number Management’ and ‘Barcode Scanner’ capabilities that can help you speed up the shipping process and level up your warehousing operations. This can also help you in the product recalling or resolving customer issues post customer delivery.

Navigating the Pick, Pack, and Ship Workflow with LionOBytes!

LionOBytes can help you navigate your Pick, Pack, and Ship Workflow with its LionO360 Cloud ERP system. Our ERP solution comes with an integrated Pick, Pack, and Ship module bolstering your business to streamline your order fulfillment, drive efficiency, and reduce costs associated to manual warehousing operations.

To acquire more information about the LionO360 ERP system’s Pick, Pack, and Ship module and how it can help navigate from ‘Warehouse to Customer’, schedule a demo with our experts.

Frequently Asked Questions

How can businesses optimize the Pick, Pack, and Ship processes?

To optimize the Pick, Pack, and Ship process, businesses are required to upgrade their system capabilities with the warehousing automation tool. Using LionO360’s ERP system integrated with the warehousing management module, you can optimize and streamline your Pick, Pack, and Ship workflow.

How can the Pick, Pack, and Ship module of the LionO360 ERP system help improve my customer satisfaction?

Using the LionO360 ERP system’s Pick, Pack, and Ship module, you can efficiently locate the customer-ordered product in the warehouse. For instance, in which specific rack or bin the product is kept. This helps in a quick and efficient pick-up process for faster order fulfillment.

Once the pickup is performed, the product is sent to the packing process that involves verification and labeling ensuring that the right product is being packed and the right information is being mentioned on the packed item.

With this, the product is ready to ship. This step ensures accuracy and quality assurance in the order delivered to the customer.

When it comes to the Shipping stage, you can choose and leverage different shipping methods and terms ensuring seamless and satisfactory customer delivery.

Is the Pick, Pack, and Ship Process Integrated with ERP or WMS Systems?

LionO360 ERP (Enterprise Resource Planning) system comes with the integrated Pick, Pack, and Ship module.